Robotics isn’t just for sci-fi movies anymore; it’s a dazzling world where machines take on roles that once belonged solely to humans. From vacuuming your living room to building cars, the types of robotics are as varied as the tasks they tackle. Imagine a robot that can flip pancakes while reciting Shakespeare—okay, maybe not yet, but the possibilities are endless! In today’s fast-paced tech landscape, understanding the different types of robotics can give anyone a competitive edge. Whether it’s industrial robots streamlining manufacturing or service robots catering to our every whim, each type offers unique benefits. So buckle up and get ready to explore the fascinating realm of robotics, where the only limit is your imagination (and perhaps your Wi-Fi connection).

Types of Robotics

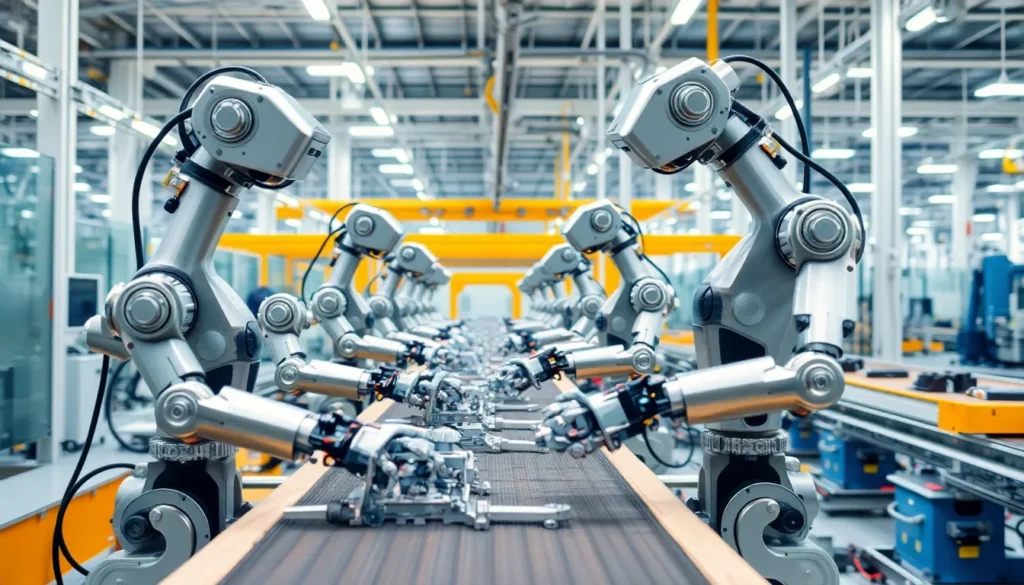

Robotics comprises various types designed for specific tasks and applications. Industrial robots often excel in manufacturing environments, performing repetitive tasks with precision. These machines streamline assembly lines, enhancing productivity and reducing labor costs. Service robots assist in everyday activities, ranging from cleaning to personal care. Cleaning robots, like vacuum robots, utilize sensors to navigate spaces autonomously. Healthcare robots support medical professionals, aiding in surgeries and patient care. Mobile robots represent another crucial category. These devices navigate environments, either autonomously or through remote control. Autonomous vehicles, for example, are a significant advancement, utilizing advanced sensors and AI to drive safely. Collaborative robots, or cobots, work alongside humans in shared spaces. They enhance safety and productivity by assisting rather than replacing workers. This type of robotics is becoming more prevalent in various sectors, including manufacturing and logistics. Military robots focus on defense applications. They perform tasks such as reconnaissance, bomb disposal, and logistics support. These robots enhance operational efficiency and safety for military personnel. Educational robots provide engagement in STEM fields. They help students learn programming, automation, and robotics principles through hands-on experience. This type of robotics fosters innovation and creativity among learners. Each of these types plays a significant role in the rapidly advancing field of robotics. Understanding the diversity of robotics helps individuals and organizations embrace technological advancements effectively.Industrial Robotics

Characteristics of Industrial Robots

Industrial robots exhibit key traits that define their performance. They often feature programmable logic controllers, allowing for versatile operations. High speed is characteristic, enabling them to perform tasks faster than human workers. Precision stands out, as they consistently deliver accuracy in repetitive tasks. Operators find them adaptable, able to function in various manufacturing processes. Many industrial robots come with safety features, ensuring secure interactions with human workers.Applications in Manufacturing

Industrial robots serve diverse applications within manufacturing settings. Assembly lines frequently utilize them to streamline production efficiency. They excel in welding processes, ensuring consistent, high-quality welds. Material handling is another application, with robots moving parts and materials seamlessly throughout factories. Quality inspection benefits from robots that employ advanced vision systems for defect detection. In packaging, robots manage tasks like labeling and final assembly, speeding up logistics and distribution.Service Robotics

Service robots play a crucial role in assisting with various daily tasks. They enhance convenience and efficiency across different sectors.Types of Service Robots

-

- Domestic robots: These robots handle household chores such as vacuuming, mowing lawns, and cleaning windows. Popular examples include Roomba for vacuuming and robotic lawn mowers for yard maintenance.

-

- Healthcare robots: Robots in this category support tasks like patient monitoring, medication delivery, and rehabilitation. Notable systems include robotic exoskeletons that assist patients with mobility challenges.

-

- Logistics robots: These robots automate warehouse operations and product delivery. Units from companies like Kiva Systems efficiently transport goods within warehouses, streamlining inventory management.

-

- Telepresence robots: Telepresence robots allow remote communication and interaction. They enable users to participate in meetings and events from afar, bridging geographical gaps effectively.